Fibrelite was approached by an OEM who provides Onshore Power Supply (OPS) systems, to quote for this large leisure cruise terminal upgrade project. The end user had previously considered...

Read MoreFibrelite is the global leader in the manufacture and development of GRP composite covers.

Fibrelite is the global leader in the manufacture and development of GRP composite covers.

Light. Strong. Composite.

Fibrelite composite access covers can be customised to suit almost any application, worldwide.

When it comes to lightweight composite technology, Fibrelite have revolutionized revolutionised the industry to become world leading pioneers.

Fibrelite was founded on two simple principles: uncompromising quality and endless innovation.

In 1980, we designed the world’s first composite manhole cover for Esso UK (ExxonMobil) – eliminating manual handling and any other health and safety issues associated with traditional metal covers.

Today, we remain at the cutting-edge of composite technology, pushing what’s possible, to fuel a new generation of maintenance-free products that meet the needs of clients across the globe.

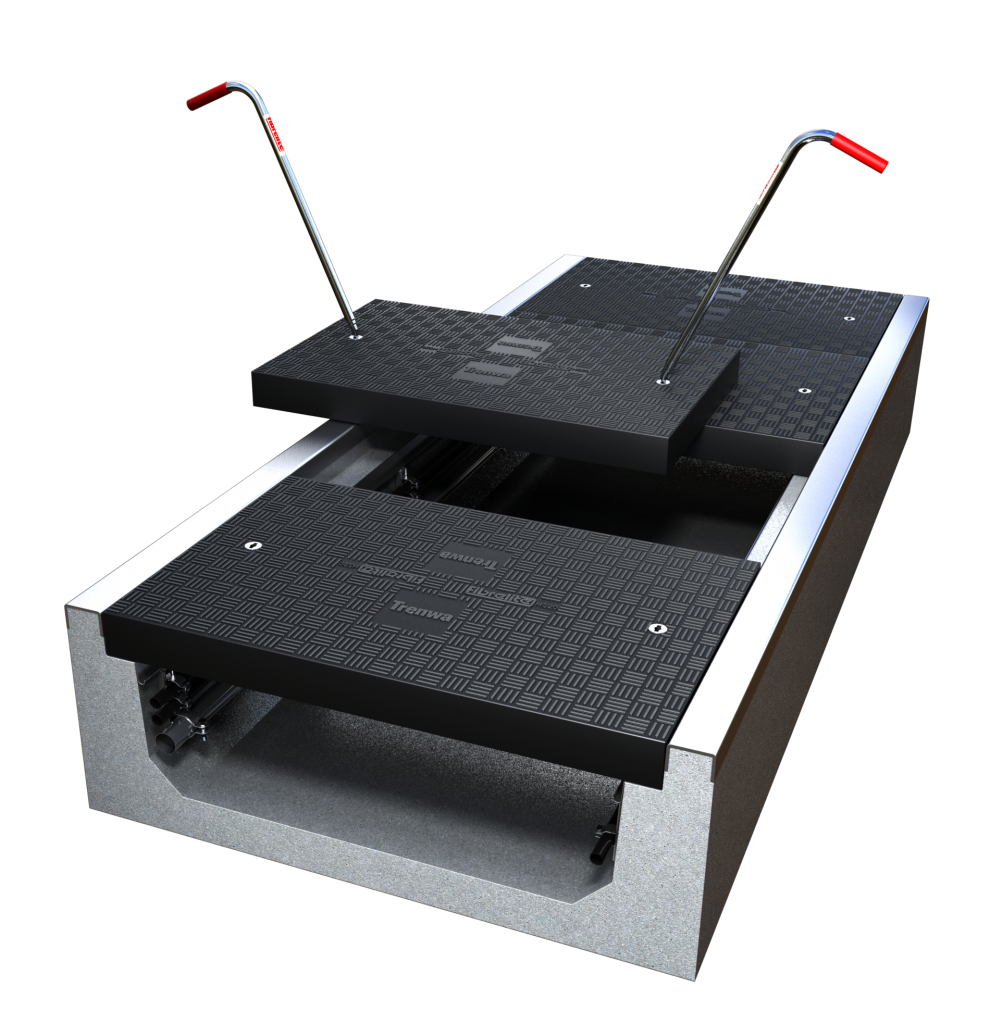

Our ground-breaking F900 load rated trench cover and multiport sealed cover system are just two examples why, from airports, ports and energy, to retail and utilities, the future of FRP GRP remains Fibrelite.

Light. Strong. Composite.

Fibrelite composite access covers can be customized customised to suit almost any application, worldwide.

When it comes to lightweight composite technology, Fibrelite have revolutionized revolutionised the industry to become world leading pioneers.

Fibrelite was founded on two simple principles: uncompromising quality and endless innovation.

In 1980, we designed the world’s first composite manhole cover for Esso UK (ExxonMobil) – eliminating manual handling and any other health and safety issues associated with traditional metal covers.

Today, we remain at the cutting-edge of composite technology, pushing what’s possible, to fuel a new generation of maintenance-free products that meet the needs of clients across the globe.

Our ground-breaking F900 load rated trench cover and multiport sealed cover system are just two examples why, from airports, ports and energy, to retail and utilities, the future of FRP GRP remains Fibrelite.

Unrivaled Unrivalled strength-to-weight the ultimate in composite engineering

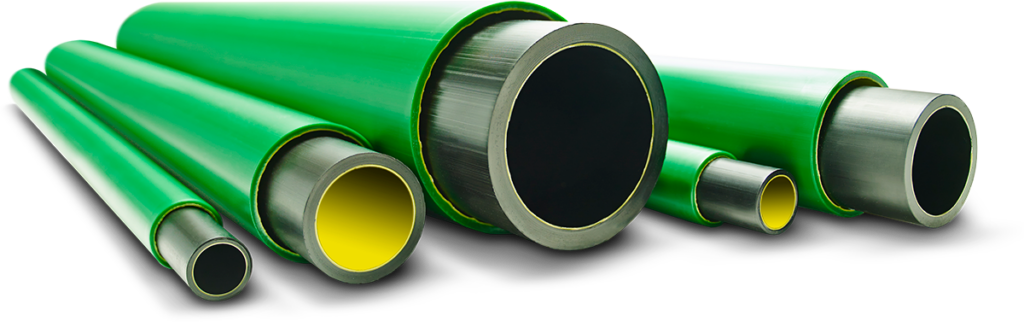

Engineered without compromise in the UK, US and Malaysia, Fibrelite is the Global Standard in Fiber Glass Reinforced Plastic (FRP) (GRP) composite manhole covers, trench panels covers and underground enclosures. We design and engineer ultra-customizable ultra-customisable solutions with an unrivaled unrivalled strength-to-weight ratio, revolutionary lightness, reassuring safety and a proven reputation for performance.

Contact us to discuss your project

Contact us to discuss your project

Fibrelite's composite access covers have the highest strength to weight ratio in the industry.

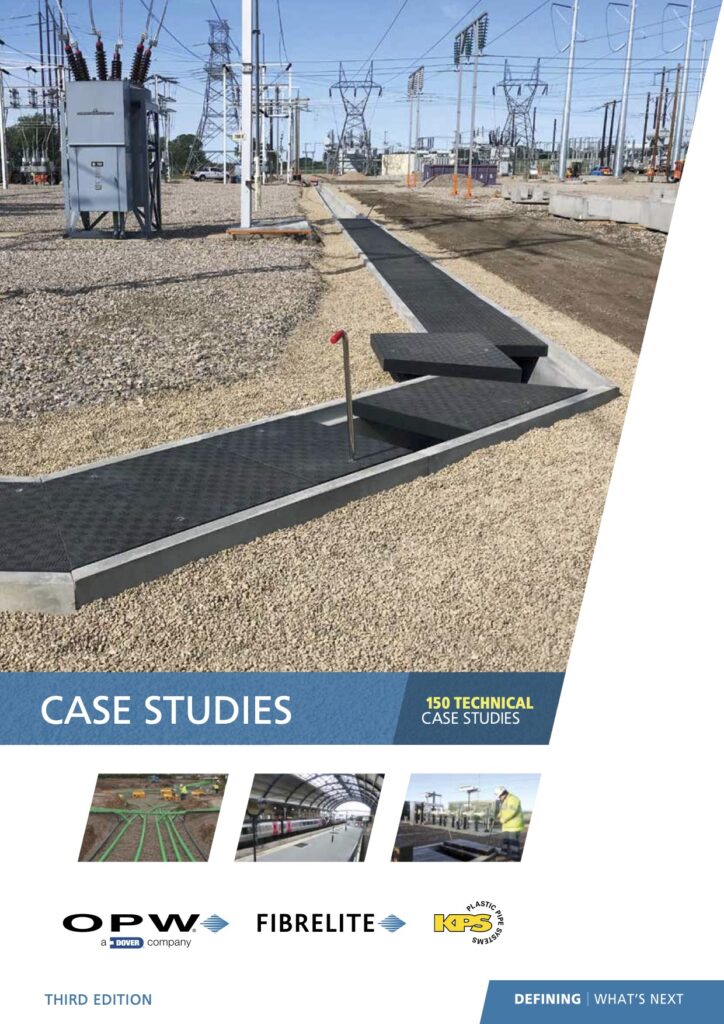

Gdansk Poland Container Terminal DCT

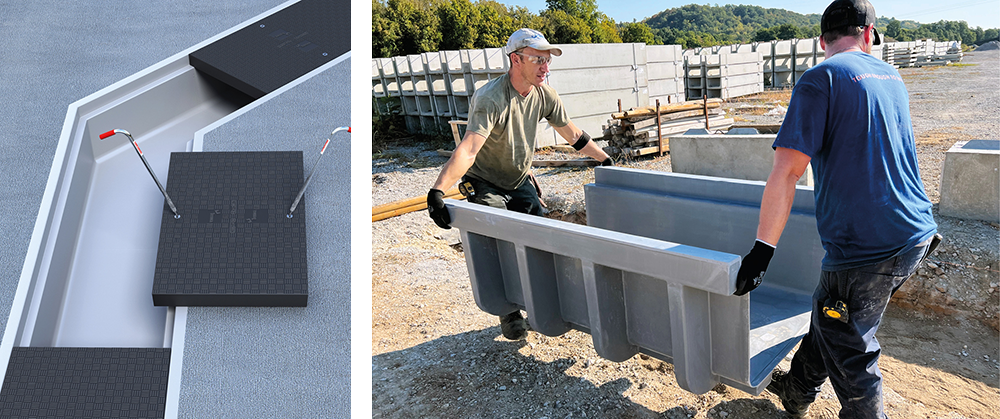

Fibrelite's custom composite covers provide safe easy access to precast concrete trenches.

UK Renewable Energy

Power Station

Fibrelite's composite covers can be customized customised to suit almost any application, worldwide.

World Class University,

Cambridge, MA

Fibrelite's composite sump systems provide the only true protection against groundwater ingress.

Worldwide Petrol Stations

Fibrelite's composite technology provides unrivaled unrivalled performance, practicality and durability.

Worldwide Petrol Stations

Water Facility, Devon, UK

Fibrelite were invited to conduct a site survey, as the... +

Read MoreLeading Middle East Oil Company

OPW is proud to show how their products provided a... +

Read MoreMajor Northern Airport, UK

Fibrelite GRP composite covers have been specified for a second... +

Read MoreCadent Gas, Warrington, UK

Fibrelite was approached by Cadent Gas to provide a long-lasting... +

Read MoreEuropean Cruise Terminal

Fibrelite was approached by an OEM who provides Onshore Power... +

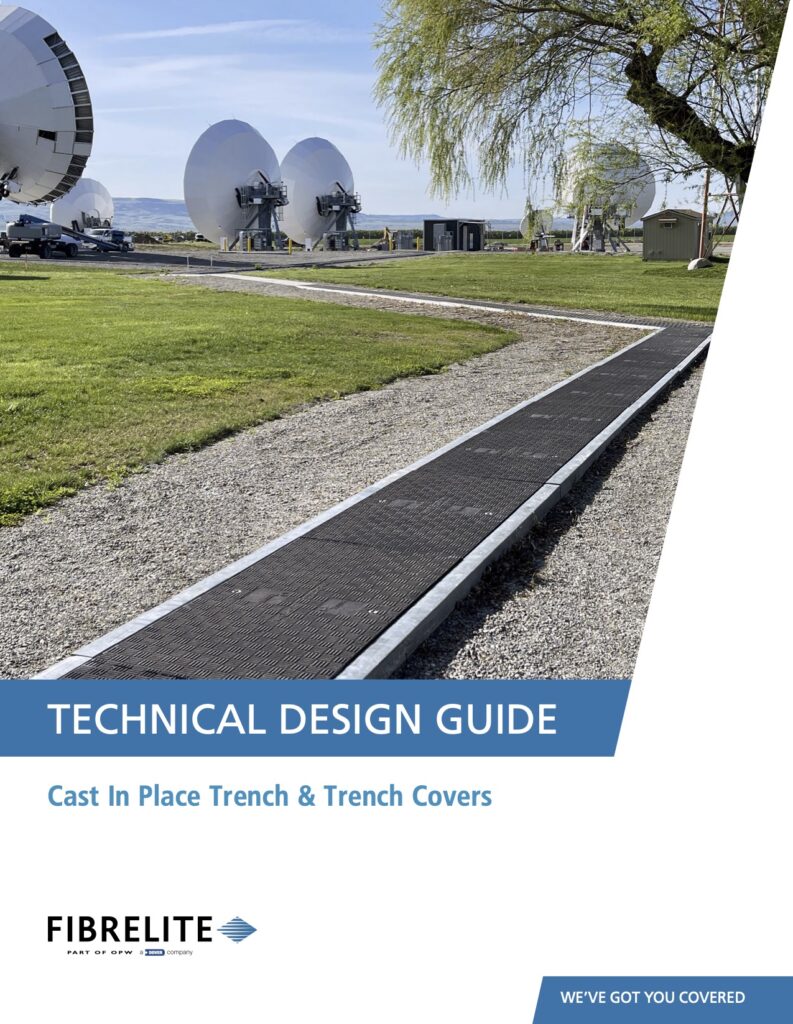

Read MoreGlobal Satellite Services Provider, USA

This large multinational satellite services provider has specified the Fibrelite... +

Read MoreWater Facility, Northumberland, UK

Fibrelite were contacted by a third-party company whose client had... +

Read MoreProducts by sectors & industries

Ports &

Airports

Gas Petrol Stations

& Forecourts

Power

Generation

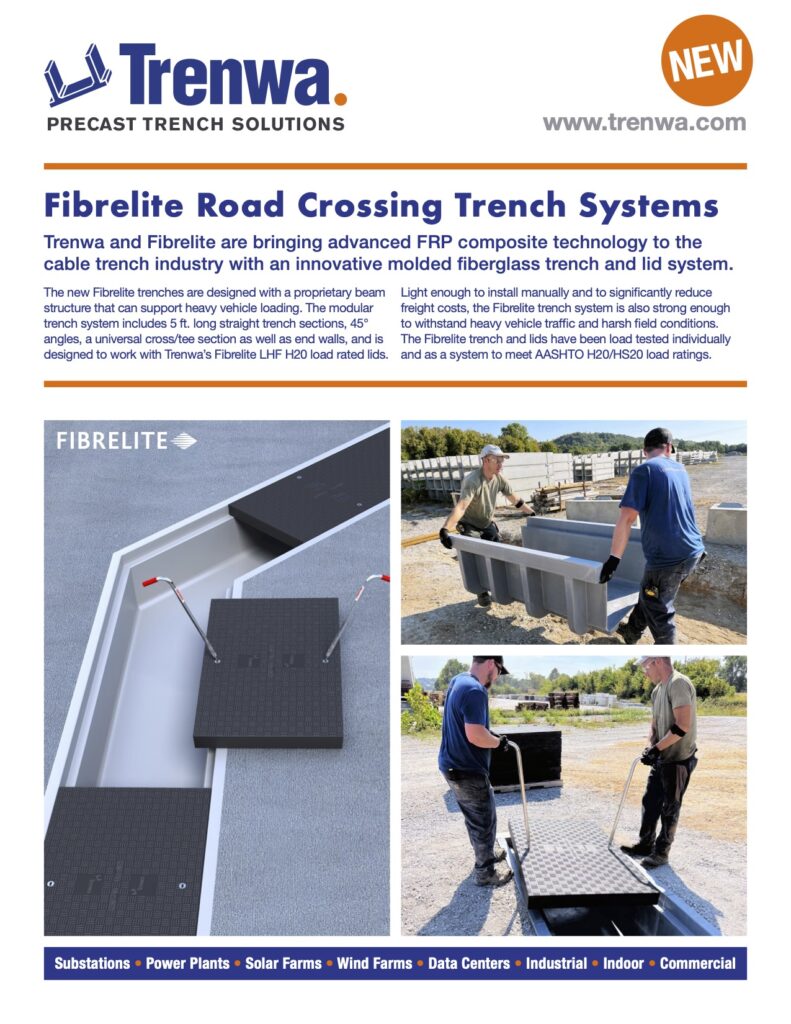

Precast Concrete Trench Systems

Data

Centers Centres

Stadiums

& Leisure

Military

& Defense Defence

Health &

Social Care

Radio

Frequency

Manufacturing

Facilities & Food Processing

Rail, Trams

& Underground

Roadside &

Access Roads

Water & Water

Treatment

Public

Areas

Shopping Centers Centres

& Retail Parks

Products by sectors & industries

Ports &

Airports

Gas Petrol Stations

& Forecourts

Power

Generation

Precast Concrete Trench Systems

Data

Centers Centres

Stadiums

& Leisure

Military

& Defense Defence

Health &

Social Care

Radio

Frequency

Manufacturing

Facilities & Food Processing

Rail, Trams

& Underground

Roadside &

Access Roads

Water & Water

Treatment

Public

Areas

Steam

Covers

Shopping Centers Centres

& Retail Parks

Products by sectors & industries

Ports

& Airports

Gas Petrol Stations

& Forecourts

Power

Generation

Precast Concrete Trench Systems

Data

Centers Centres

Stadiums

& Leisure

Military

& Defense Defence

Health &

Social Care

Manufacturing

Facilities & Food Processing

Rail, Trams

& Underground

Roadside &

Access Roads

Water & Water

Treatment

Public

Areas

Shopping Centers Centres

& Retail Parks

Radio

Frequency

Steam

Covers

Case Studies by Sectors & Industries

Featured product...

FRP GRP composite access covers for precast concrete trenches

- Painless to install. Effortless to remove

- Heavy-duty load ratings. Lightweight

- No corrosion. No maintenance

- Any shape, size, or access requirement

- Anti-slip/skid properties far exceeding health and safety advisory limits