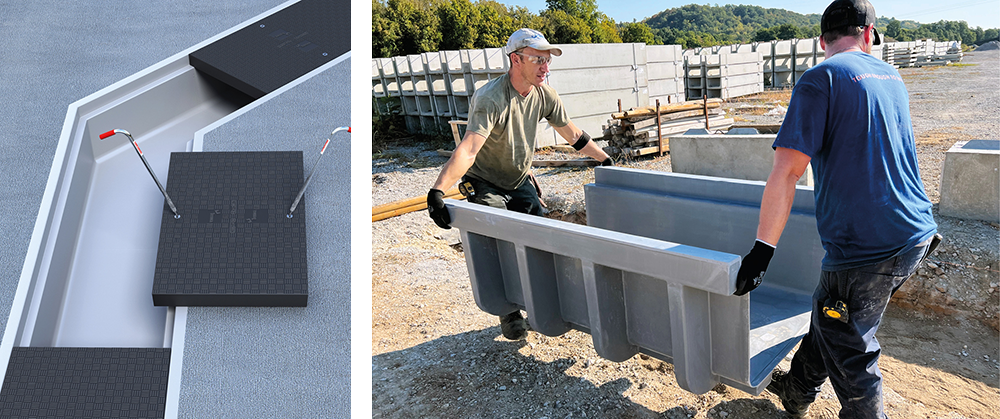

Fibrelite was approached by an OEM who provides Onshore Power Supply (OPS) systems, to quote for this large leisure cruise terminal upgrade project. The end user had previously considered...

Read More- Home

- Products

-

- Sectors

-

Select a sector/industry:

Ports &

AirportsGas Petrol Stations

& ForecourtsPower

GenerationPrecast Concrete Trench Systems

Data

Centers CentresStadiums

& LeisureMilitary

& Defense Defence

Health &

Social Care

Radio

Frequency

Manufacturing

Facilities & Food ProcessingRail, Trams

& Underground

Roadside &

Access Roads

Water & Water

TreatmentPublic

AreasSteam

CoversShopping Centers Centres

& Retail Parks

-

- Global Projects

-

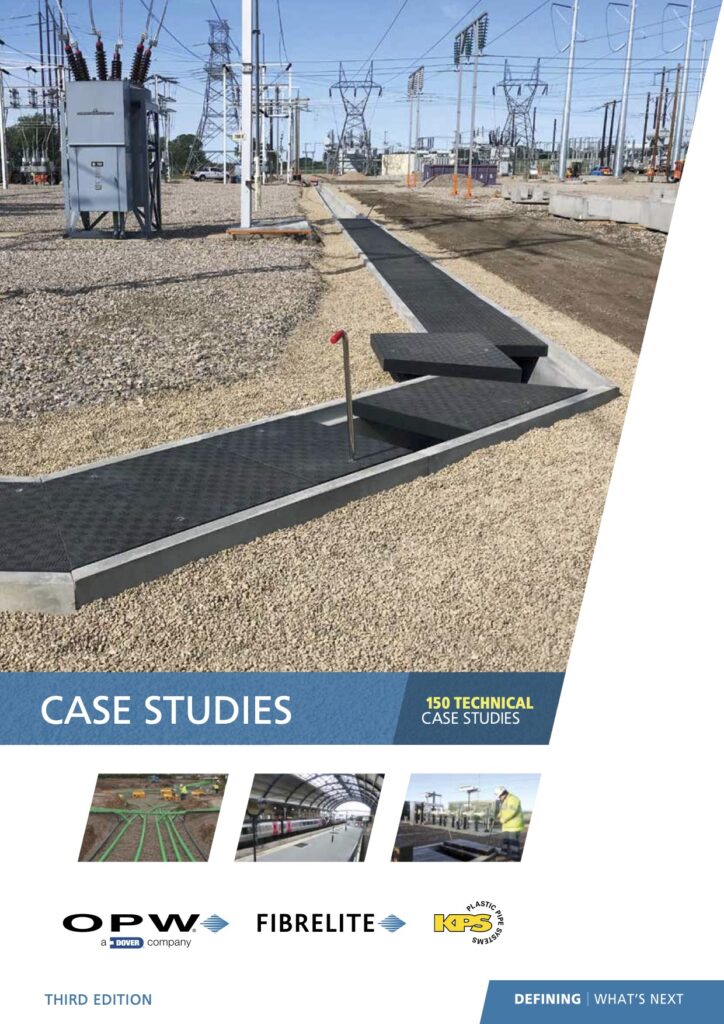

Technical case study library

Stadiums

& Leisure

Military

& Defense Defence

Health

& Social Care

Radio

Frequency

Manufacturing Facilities & Food Processing

Shopping Centers Centres

& Retail ParksTelecoms

Our latest case study:

-

- Technical Hub

-

- News

-

-

-

Latest news:

New case study! Custom F900 trench covers for one of Europe’s leading cruise terminals

In this project we were approached by an OEM who provides Onshore Power Supply (OPS) systems, to quote for this large leisure cruise terminal upgrade project.

Read MoreGlobal satellite services provider specifies Fibrelite Trenwa trench and cover system

This large multinational satellite services provider specified the Fibrelite Trenwa partnership trench and cover system for their latest satellite earth station antenna facility in the U S

Heavy trench covers are history

Once in a while a product will come along whose performance will drive a change in standards across entire industries Like stainless steel Or concrete Or a trench cover which

New case study! Busy UK regional airport upgrade to retrofit F900 Fibrelite access covers

Fibrelite provided this regional UK airport with an upgrade for their access covers over their off apron runway lighting pits Ease of access to the runway 8230

events:

-

-

-

- About Us

- Contact Us

Menu